Resources for teaching with case studies, hands-on lab and assessment exercises

These teaching resources have been developed by Timofey Shalpegin from the University of Auckland’s Business School, Information Systems and Operations Management department, to help his Stage II students in critical and reflective decision-making by using simulators of real-life scenarios in business operations management (i.e., case studies).

The project’s resources might be useful to teachers of operations management looking for mock case study exercises.

The project was supported by the SEED Fund grants for 2017.

For similar projects, see: Experience-based Learning: Engineering Systems Thinking (Engineering) and Writing Code the Visual and Kinesthetic Way (Engineering).

Project background

The goal of this project was to develop a simulator of a manufacturing company. As Timofey explained before he started his project, “The students using this simulator will be able to make key decisions for their virtual company and see how their decisions affect the company performance. The primary focus of this simulator is operations and supply chain management decisions. In particular, it will require students to identify competitive capabilities of a company, to forecast future demand, to develop capacity management, quality control, new product development, inventory management and supplier selection policies. The students will be able to compare their results to the other students who are taking or have taken the same course.”

It was envisaged that the simulator would run during Semester Two, 2017, and would involve 12 simulation rounds (one round per week). After each second simulation round, the students would be asked to write “a short essay explaining the decisions they made and the results they achieved. The purpose of these essays is to help students link the theoretical knowledge they get from the lectures with the practical experience they get from the simulator. This way, the students will experience the basic principles of operations and supply chain management as early as in week one, and then they will gradually build up their skills by acquiring theoretical knowledge from week to week. Weekly essays will ensure than the students analyse their progress and get timely feedback.”

Timofey noted that there were already several off-shelf simulators available on the market. However, the existing simulators were unfit for use for several reasons:

1. They had been developed 10-20 years ago and thus did not incorporate the latest advances of management science;

2. They were not customised for the specific material developed and taught at our university; and

3. They were expensive, ranging from $1,000 to $1,500 per semester for a standard class size of 80-100 students.

For these reasons, Timofey believed the development of the university’s own simulator should be seen as an important and high-priority project.

Timofey wanted to use the SEED Fund grant to develop a user-friendly interface of the simulator, spending the funding on software development and testing. An important part of the project was to embed data-visualisation tools that would help students “understand the impact of their previous decisions and make the decisions for the next round of simulation”. Another necessary step of development was “extensive testing of the simulator before it is launched, which implies a significant tester workload”. At the time of grant application, Timofey was already working on development of the simulator engine (“the most resource consuming part”) as an extracurricular activity.

Click below to read Timofey’s reflection on his project after its completion.

Project reflection

What were the objectives of your project?

We planned to develop a company simulator which would allow students to make various operations management decisions from forecasting to inventory management, to capacity management. Its goal was to enhance students’ learning by allowing them to make key operations decisions for a simulated company.

What went well? What was unexpected?

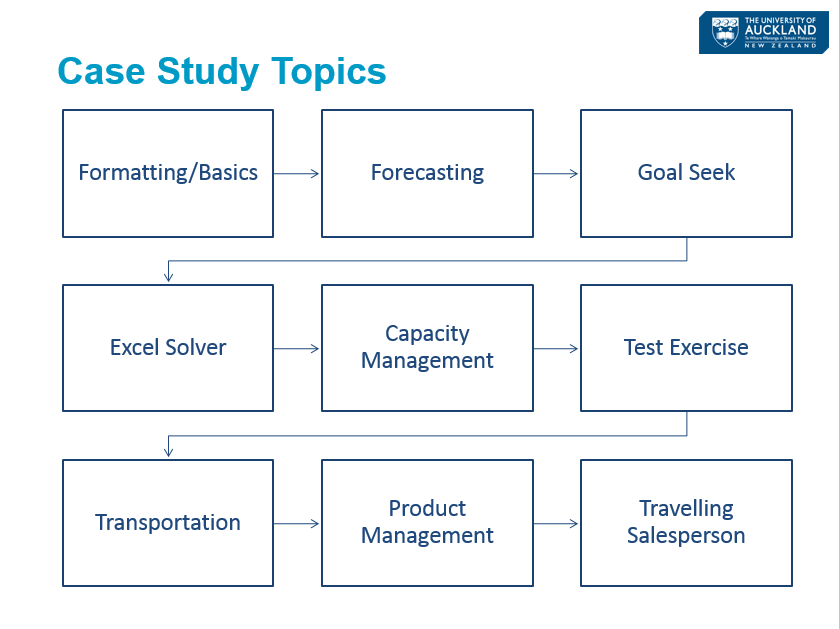

We developed a set of nine independent mini-case studies simulating different operations management environments. Each case study contains three main parts:

- the exercise the tutor explains at the lab session,

- the exercise the students need to complete on the own with tutor help available, and

- the assessment exercise students need to complete after the lab.

In this respect, we achieved the goal of the project.

While developing the project, we made a strategic decision to develop nine separate case studies rather than a single simulator. This way students can understand concepts more quickly and they can perform well even if they failed at one of the previous concepts. It also decreased the development cost significantly and gave us more flexibility in choosing the order in which different topics are introduced to the students.

How did the project contribute to your students’ learning? (How do you know?)

While we have not completed a proper study measuring students’ learning yet, we believe that more hands-on exercises enhance students’ abilities to think critically and solve complex problems. We will conduct a more thorough study next semester [in 2018], once the students go through all the case studies designed. Nevertheless, at this stage we received a positive feedback from tutors having tested the exercises.

The resources we built also reinforced the connection between the theoretical concepts discussed in lectures and the lab sessions. This will greatly help students without relevant work experience who currently struggle linking these two pieces together. Furthermore, the writing component of the project will help our students reflect on the results they obtain and discuss their implications.

How did the project contribute to your learning?

It helped us find a better course structure for OPSMGT 255, Introduction to Operations and Supply Chain Management course. We restructured the course and rearranged different topics to make sure students start from relatively simpler problems and gradually progress to more difficult ones. We also learnt some new applications of Excel tools to be used in the operations management context.

Do you plan to continue this initiative beyond the grant period?

The newly-designed case studies will definitely remain in the course curriculum after the grant period. We have redesigned the lab sessions to ensure that the new structure is well accommodated. It will also change the assessment structure as currently students can get marks for participating in lab sessions without completing an assignment. After the full-scale implementation next semester, we plan to enhance the project even further by adding an element of competition to it.

Resources

Project overview (.pptx presentation)

Teaching materials for nine mini-cases:

Blending

In-class exercise (solution) (MS Excel Worksheet)

Blending problem (MS Word Document)

Assignment solution (MS Excel Worksheet)

In-class example (MS Excel Worksheet)

In-class example (solution) (MS Excel Worksheet)

Assignment (MS Excel Worksheet)

In-class exercise (MS Excel Worksheet)

Capacity Planning

In-class exercise (MS Excel Worksheet)

In-class exercise (solution) (MS Excel Worksheet)

Assignment solution (MS Excel Worksheet)

Capacity Planning (MS Word Document)

Capacity Planning example (MS Excel Worksheet)

Capacity Planning example (solution) (MS Excel Worksheet)

Assignment (MS Excel Worksheet)

Goal Seek

In-class exercise (MS Excel Worksheet)

In-class exercise (solution) (MS Excel Worksheet)

Goal-seek instruction (MS Word Document)

In-class example (solution) (MS Excel Worksheet)

In-class example (MS Excel Worksheet)

Lab 1

Excel Introduction (formal) (MS Excel Worksheet)

Excel Introduction (solution) (MS Excel Worksheet)

Lab one instruction (formal) (MS Word Document)

Lab 2

OPS 255 Lab 2 (formal) (MS Excel Worksheet)

02 Forecasting (MS Powerpoint Presentation)

OPS 255 Lab 2 Instruction (MS Word Document)

Ops 255 Lab 2 (formal, solution) (MS Excel Worksheet)

Lab Solver Intro

Class exercise (MS Excel Worksheet)

Lab 3 Class (MS Excel Worksheet)

In this lab (MS Word Document)

Assignment solution (MS Excel Worksheet)

Assignment (MS Excel Worksheet)

Lab 3 Class (solution) (MS Excel Worksheet)

Class exercise (solution) (MS Excel Worksheet)

Mid-Term Excel

Question 1 (solution) (MS Excel Worksheet)

Question 1 (MS Excel Worksheet)

Transportation

In-class exercise (solution) (MS Excel Worksheet)

In-class example (MS Excel Worksheet)

Assignment solution (MS Excel Worksheet)

In-class example (solution) (MS Excel Worksheet)

Partial Absolute reference (MS Excel Worksheet)

Assignment (MS Excel Worksheet)

In-class exercise (MS Excel Worksheet)

Transportation lab instruction (MS Word Document)

Travelling Salesperson

Evolutionary Solver (MS Word Document)

Traveling Salesperson example (solution) (MS Excel Worksheet)